Specialized Rough Machining Reduces Waste, Tool Wear, and Can Improve Mechanical Properties

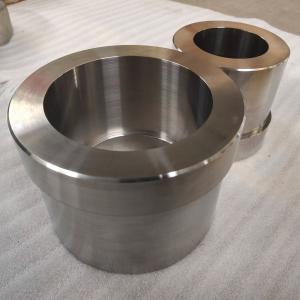

FAIRFIELD, NJ, UNITED STATES, August 18, 2025 /EINPresswire.com/ -- In advance of FabTech 2025, All Metals & Forge Group (AMFG) announced its enhanced capability to produce precision near-net-shaped forgings that support the demands of today's most challenging applications as manufacturers seek greater efficiency and durability from forged components. While the company has long offered forgings as rough-machined parts, recent upgrades in equipment and process control have further optimized AMFG’s ability to provide near-net geometries with minimal waste and improved material performance. Miniature examples of these forgings will be highlighted at FabTech 2025 at McCormick Place in Chicago, IL, September 8-11.

Unlike starting from a large forged block that

Key advantages of near-net-shaped forgings include:

Reduced machining waste and processing time

Uniform mechanical properties in complex geometries

Improved heat treatment performance at depth

Flexibility in design for specialized applications

Better performance in extreme environments

Potential cost savings compared to traditional forging workflows

For engineers developing new products or optimizing existing designs, near-net-shape forgings offer a practical, high-performance solution. As industry moves toward smarter, more sustainable manufacturing, these components are helping to unlock stronger, lighter, and more reliable parts.

All Metals & Forge Group can be found at Booth A3198 in the South Building of McCormick Place at FabTech 2025, September 8 through 11.

About All Metals & Forge Group

All Metals & Forge Group produces open die forgings and seamless rolled rings—rough, near net, or finish machined—for commercial and industrial uses in standard shapes or complex geometries. AMFG provides heat treating to modify mechanical properties for unique applications. Finish machining is available for ready-to-use parts.

AMFG forges alloys from 7 metal families: Alloy, Carbon, Stainless and Tool Steels, Nickel, Aluminum and Titanium. The company stocks over 100 metal alloys and can custom-smelt hard-to-find or specialized alloys for specific applications.

AMFG delivers forgings and finish machined parts to more than 60 countries in North America, Central America, South America, the UK, EU, Eurasia, the Middle East, Australia, and Africa. Industries supported include Aerospace, Defense, Power Generation, Engine and Turbine, Food Processing, Gear Makers, Machine Building, Tier-1/Tier-2/Tier 3 Machine Shops, Mining, Oil and Gas, Pulp and Paper, Petroleum and Chemicals, Shipbuilding, Transportation, and Valves and Pumps.

AMFG holds certifications for ISO9001, AS9100, ABS, API 6A, PED, and TUV. The company produces products to industry standard specifications including ASTM, ASME, AMS, SAE, AISI, EN, DIN, and OEM.

No comments:

Post a Comment